ICHIKOH History

1903~From oil lamps to electric lamps

Founded 1903–1940

-

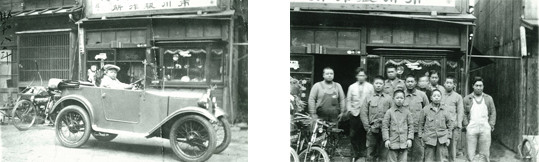

Founding of Hakkosha in 1903 as a specialist plant for white-light wax oil and signal lamps. Development of high-luminance oil lamps that overwhelmingly outperform contemporary competitors

-

Founding of Ichikawa Seisakusho in Kyobashi as an auto parts manufacturer

Manufacture and sale of taillights and safety signal equipment

-

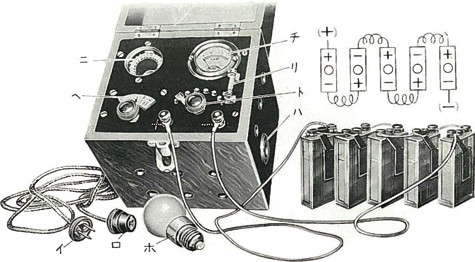

Hakkosha product: railway lighting equipment

Steam locomotive headlight

-

Ichikawa Seisakusho: development of automobile replacement parts

Headlights, rear combination lamp, fender mirrors, rearview mirrors, radiator grilles, hubcaps

-

Success with storage batteries for signal lights

-

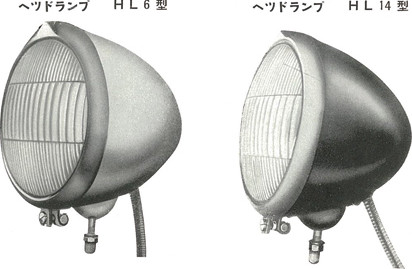

Successful domestic manufacture of automobile headlights

-

Appearance of first domestically mass-produced Datsun cars

Development of Hakkosha headlights (1932 Type 11 Phaeton)

-

Establishment of Ichikawa Seisakusho Co., Ltd.

-

Establishment of Hakkosha Co., Ltd.

1940~Arrival of Sealed Beam and Halogen Lamps

1940–1980

-

Arrival of ready-to-assemble headlights

Ready-to-assemble headlights using tungsten bulbs

-

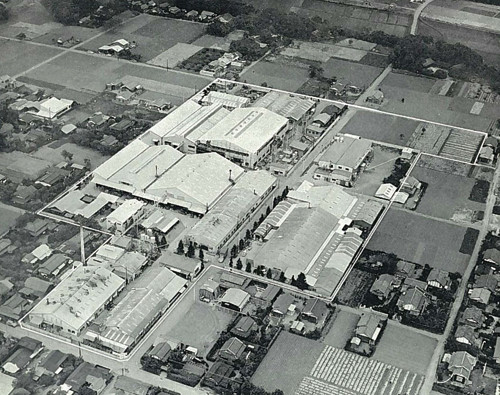

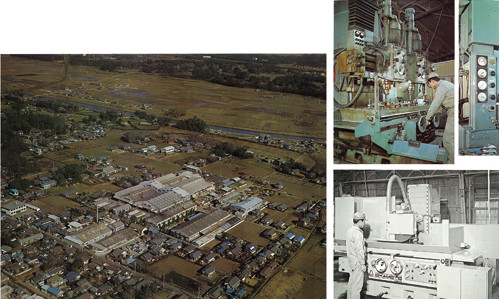

Construction of Hasuda Plant of Hakkosha

-

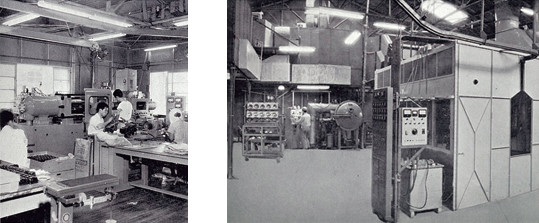

Success with first vacuum deposition in Japan

-

Establishment of Tamagawa Plant of Ichikawa Seisakusho

-

Delivery of lights for Nissan-assembled Austin cars

-

Establishment of Maruko Plant

-

Early adopter of plastics for technical innovation

-

Listing of Hakkosha Industries and Ichikawa Seisakusho on the Tokyo Stock Exchange Second Section

Major order for Nissan Bluebird parts

-

Construction of Isehara Plant

-

Spin off of repair parts sales division to establish Ever Ace (now PIAA)

-

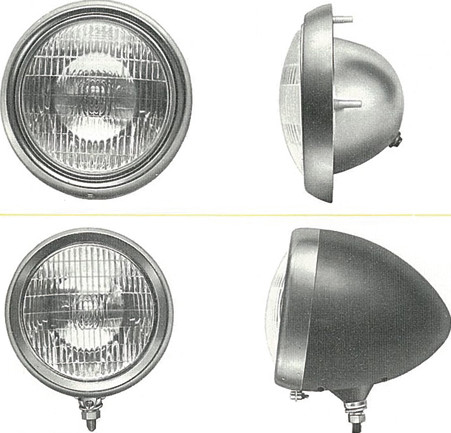

Arrival of sealed beam headlights

Establishment of Fujioka Plant No. 1 in Fujioka, Gunma Prefecture

-

Partnership agreement between Hakkosha Industries and Ichikawa Manufacturing

-

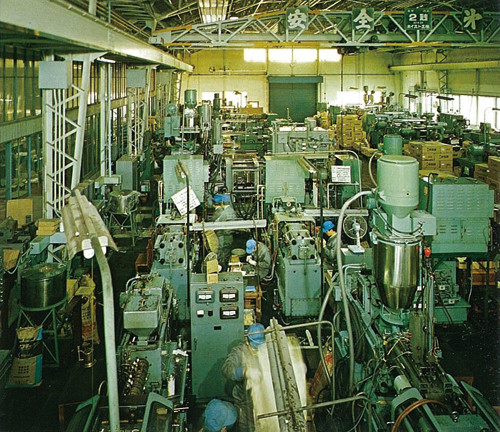

Merger of Hakkosha Industries and Ichikawa Manufacturing, establishing Ichikoh Industries, Ltd.

-

Establishment of Fujioka Plant No. 2 in Fujioka, Gunma Prefecture

-

Arrival of diverse headlights of various shapes along with the rise of halogen bulbs

-

Change of listing to Tokyo Stock Exchange First Section

-

Construction of Oizumi Plant in Ora-gun, Gunma Prefecture

-

Arrival of Japan's first electric remote control fender mirrors, on the Nissan Laurel (C130)

1980~Arrival of HID Light Source

1980–1999

-

Development of Japan's first mass-produced retractable headlights, for the Nissan Pulsar

-

Capital participation in NAL in Illinois, USA

Development of the world's first electric retraction mechanism for door mirrors disseminated worldwide (C32 Laurel)

-

Installation of world's first LED high mount stop lights, on the Nissan Fairlady Z (Z31)

-

Development of first domestically-produced projector headlights

Establishment of IMI in Kentucky, USA

-

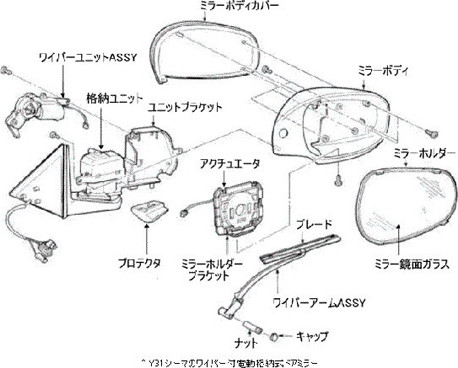

Installation of the world's first door mirrors with wipers, on the Nissan Cima, which was so popular it was called the "Cima phenomenon" in Japan

-

Installation of the world's first four-lamp projector headlights, on the Nissan Silvia (00)

Compact mounting of miniaturized wiper drive unit and wiper arm on mirror with electric remote control and retraction functions

-

Establishment of Ichikoh Malaysia SDN, BHD, in Malaysia

-

Realization of HID headlights using high-pressure discharge for high-intensity light, and development for use in endurance racing

Commencement of operation at new Nakatsugawa Plant

(Cedric/Gloria Y32) Development of world's first ultrasonic rain-shedding mirror, which uses ultrasonic waves to vibrate the mirror's surface and shed raindrops

-

Development of high-efficiency free surface headlights for mass-produced vehicles

-

Establishment of PT. Ichikoh Indonesia in a suburb of Jakarta, Indonesia

-

Installation of Japan's first LED rear combination lamp, on the Nissan Gloria (Y34)

2000~LED, the Evolving Next-Generation Light Source

2000–2010

-

Establishment of new plant of joint venture company Kenkoh Industries, Ltd., in Changhua, Taiwan

Comprehensive business alliance with Valeo for lighting business

-

Establishment of Wuxi Koh Sean Technology Co., Ltd. as a joint venture in Wuxi, China

-

World's first installation on door mirrors of LED turn signals, infrared LEDs for night lighting, and cameras, on the Nissan Elgrand (E51)

Installation of the world's first large LED light source overhead consoles incorporating dome lamps, spot lamps, etc., on the Toyota Mark X

-

Signing of technical support agreement with FIEM

Installation of AFS on the Toyota Alphard

Beginning of provision of racing headlights to the Tokai University Le Mans Project

-

Development of dome lamps for official Imperial Family cars, with Milky Way concept, light source of 1,500 warm white LEDs, internal diffusion, and lens surfaces processed with Japanese paper

Establishment of Foshan Ichikoh Valeo Auto Lighting Systems Co., Ltd., in China

Establishment of Ichikoh Mitsuba Inc. (IMIC) in Kentucky, USA

-

Transfer of fixed assets from the former Oizumi Plant and Nakatsugawa Plant sites and the Head Office site

-

Agreement on global alliance with Ficosa International

Completion of I-WING technical center at Isehara Plant

Compared to conventional (HID) up to 2010, using half the electricity while providing the same brightness, the world's most efficient automobile LED headlights for the Nissan Leaf achieve long life twice that of HID (5,000 hours: equivalent to about 20 years' usage), utilizing reflectors and contributing to lighter weight and low cost

Integration of Head Office functions, formerly sited in Gotanda, with the Isehara Technical Center in order to increase efficiency

2011–So That We Will Still Be a Company That Is Shining 100 Years from Now

2011–

-

August

Strengthening of the alliance between Ichikoh and Valeo in China Establishment of Valeo Ichikoh Holding Ltd. in Dublin, Ireland

Unification of lamp business in the China region as the holding company of FIV, Shenyang Valeo, Wuhu Valeo, and Hubei Tech Center

October

Construction of a new plant of Ichikoh Industries (Thailand) Co., Ltd., in Amata, Rayong, Thailand. It is Ichikoh's second largest plant after Isehara Plant and the largest overseas plant. Introduce the latest production facility and feature a technical center that enables local product design and development.

-

February

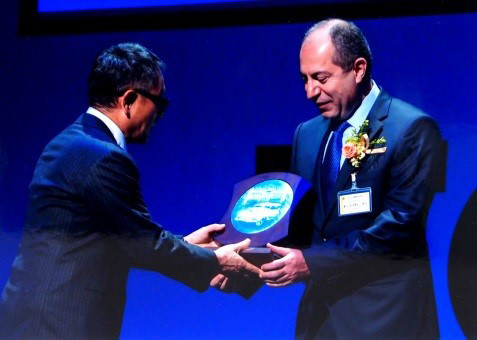

Receipt of Innovation Award from Toyota for the first time

Receive an Innovation Award from President of Toyota, Akio Toyoda at the Toyota Global Supplier Convention on February 27, 2015 (Fri.).

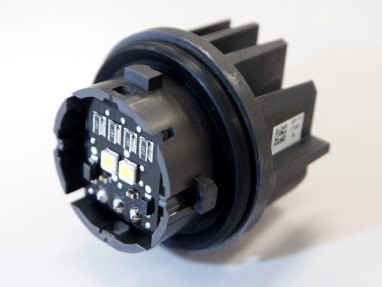

The product introduces MonoLED and has been installed on the new Alphard/Vellfire.

(Photo) MonoLED, winner of the Innovation Award

(Photo) Ichikoh President Ali Ordoobadi accepting the award from Toyota President Akio Toyoda.(Position titles at time of ceremony)

-

January

Become a consolidated subsidiary of Valeo Bayen as a result of a tender offer for Ichikoh shares by Valeo Bayen.

-

June

Construction of the Atsugi Plant (Atsugi-shi, Kanagawa-ken) which specializes in headlamps.

Implementation of Lean Production System based on the innovative production concepts of Valeo, along automation such as collaborative robots, AGV or Automated Warehouse management.